CAMERAS

JKINDUSTRIAL & DATA TRANSCEIVERS AND MULTIPLEXERS OSD138 UNIVERSAL DATA TRANSCEIVER

PRODUCT DESCRIPTION

- The HEPZWM wall mount bracket can be installed on any interior or exterior wall, and is compatible with the HEPZPMA pole mount adapter and HEPZCMA corner mount adapter.

- The HEPZPMA pole mount adapter is suitable for use on poles between 110–150 mm (4.3 and 5.9 inches) in diameter. It can be used on its own or in conjunction with the HEPZWM wall mount bracket.

- The HEPZCMA corner mount adapter lets you install cameras securely on any outside corner. It can be used on its own or in conjunction with the HEPZWM wall mount bracket.

equIP Series Explosion-Proof PTZ Cameras Mounts and Accessories

FEATURES AND BENEFITS

equIP Series Explosion-Proof PTZ Cameras Mounts and Accessories

FEATURES AND BENEFITS

ORDERING INFORMATION

HEPZPMA

HEPZCMA

HEPZPRM

HEPWS

HEPZA04

HEPZA10

HEPZT04

HEPZT10

specifications

Request a Quote

Learn More From

Frequently Asked Questions

Multimode fiber commonly comes in 50/125 μm or 62.5/125 μm core/cladding dimensions, with bandwidth capacities ranging from 200 MHz to 2 GHz, depending on the grade. Multimode systems typically support transmission distances of up to 5 km, making them suitable for short- to medium-range applications.

In contrast, singlemode fiber—usually 9–10/125 μm—offers significantly lower attenuation and effectively unlimited bandwidth, supporting links over 150 to 200 km, especially when paired with optical amplifiers and advanced transceivers.

While singlemode fiber is less expensive per meter, its associated transceivers and equipment tend to cost more than their multimode counterparts. That said, singlemode devices are generally compatible with both singlemode and multimode fiber, whereas multimode equipment works only with multimode fiber.

Let me know if you’d like this turned into a quick-reference table or visual comparison—it’d make a solid inclusion for a fiber deployment guide.

The link budget is the difference between the transmitter’s output power and the receiver’s sensitivity. This budget must account for all signal losses along the path, including:

- Fiber attenuation due to the transmission medium

- Connector losses, such as those at patch panels or equipment interfaces

- Splice losses from mechanical or fusion joints

- Link margin, which provides a buffer for unforeseen variations

The link margin typically ranges from 2–3 dB in tightly controlled environments to up to 10 dB in more variable conditions. It is designed to accommodate:

- Component aging (e.g., light sources may degrade and lose up to 3 dB over time)

- Temperature variations affecting transmitter output or receiver sensitivity (up to 3 dB may be needed for thermal fluctuations)

- Physical cable damage and repair-induced losses (usually minor, but more relevant in harsh or industrial settings)

Always design your system for worst-case scenarios to ensure reliability. However, don’t overlook the best-case condition either—some optical receivers may exhibit erratic behavior if the incoming signal is too strong.

First, verify the optical signal strength along the link. Use an optical power meter to measure the received power at the fiber’s end point. Typical transmit levels range from –8 dBm to –15 dBm, while the receiver sensitivity is around –31 dBm, giving you a link budget of approximately 16 dB. This margin supports transmission distances of up to 10 km on singlemode fiber and about 3–5 km on multimode fiber.

If the measured power falls below the receiver sensitivity, there’s a strong likelihood of issues with the installed fiber. Ideally, initial OTDR readings should have flagged such faults.

If not, inspect the patch cords currently in use for possible defects or misalignment. A frequent oversight is the use of mismatched patch cords.

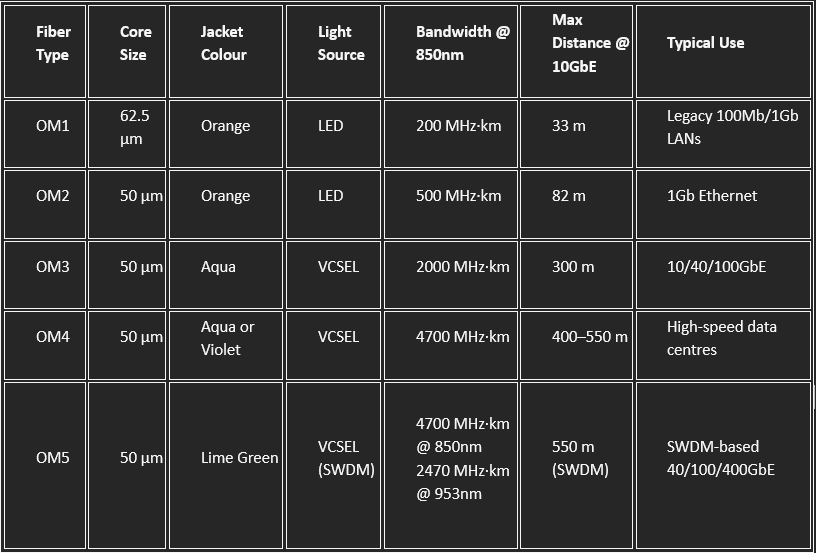

Multimode fiber types are classified by the ISO/IEC 11801 standard into five main categories: OM1, OM2, OM3, OM4, and OM5. Each type differs in core size, bandwidth, supported data rates, and maximum transmission distances. Here’s a quick breakdown:

- OM3 and OM4 are laser-optimized and widely used in modern data centers.

- OM5 supports shortwave wavelength division multiplexing (SWDM), enabling multiple wavelengths over a single fiber for higher capacity.

- All OM types are backward compatible in terms of connectors, but mixing core sizes (e.g., OM1 with OM3) can cause performance issues.